How Are US Manufacturing Leaders Adopting AI and Machine Learning to Drive Growth in 2025?

Author: Minhal Abbas

2 July, 2025

The United States is experiencing a revolutionary shift in the manufacturing world. With the power of AI services and custom AI development, manufacturers are becoming more efficient by speeding up product innovation and reducing production costs.

In this guide, you will explore how US manufacturing companies are adopting AI and ML technologies. You will also learn about the latest AI solutions, real-world use cases, and how Xorbix Technologies implements AI and ML software that can fulfill companies’ manufacturing needs.

The Current State of AI Adoption in US Manufacturing

According to US Census Bureau data, trends in AI adoption among the manufacturing industry are becoming increasingly common. More than 52% of manufacturers have implemented an AI strategy (in some form). This pace of acceleration shows that it’s no longer an experiment to develop AI; it’s a business strategy.

Based on Global Market Insights, the AI in manufacturing market for artificial intelligence has already reached $4.2 billion in 2024 and is expected to experience dramatic growth at a compound annual growth rate (CAGR) of 31.2% from 2025 to 2034. This significant investment indicates that industry leaders understand that AI-driven services can demonstrate outstanding returns through enhanced productivity, better quality control, and optimal business operations.

Key Areas Where Manufacturers Are Implementing AI Solutions

U.S. manufacturing companies are using AI and machine learning to optimize maintenance, improve quality control, and streamline operations. By adopting AI solutions, they gain efficiency, reduce costs, and stay competitive in a rapidly evolving industry. Key areas to implement AI in manufacturing sectors are given below:

Predictive Maintenance and Equipment Optimization

Manufacturers are increasingly adopting AI-based predictive maintenance systems to reduce expensive downtime and increase the life of their equipment. The IoT machine learning algorithms process sensor data from production equipment to discover potential failures before they become failures and help to plan maintenance proactively.

Computer-Vision Quality Inspection and Defect Detection

Quality assurance is transformed by Computer Vision and Machine Learning. Xorbix AI-powered systems can check items at much faster rates than humans with the same levels of accuracy. This use of AI has been particularly useful in industries where quality is a key requirement and zero-defect manufacturing is the objective.

Go to our case study “Modernizing Heavy Equipment Operations with a Multi‑Platform Manuals & Documentation Tool”. In this case study, users can understand how Xorbix AI solutions streamline maintenance and reduce downtime for manufacturing equipment.

Supply Chain Intelligence and Demand Forecasting

Through forecasting, manufacturers can better manage their inventory and supply chain using AI solutions. Machine learning algorithms can calculate vast amounts of historical data, market trends, and external factors to predict demand patterns in an unprecedented way.

Our Xorbix case study on “Forecasting the Future: AI and ML Reshape Artisanal Sales” shows how our AI and ML development solutions boost production planning and delivery.

Generative Design & Simulation

Generative AI-driven solutions with optimal product configuration allow testing multiple sites or projects. It enables faster prototyping and minimizes the burden of physical testing. This drives accelerated innovation while minimizing risk and cost.

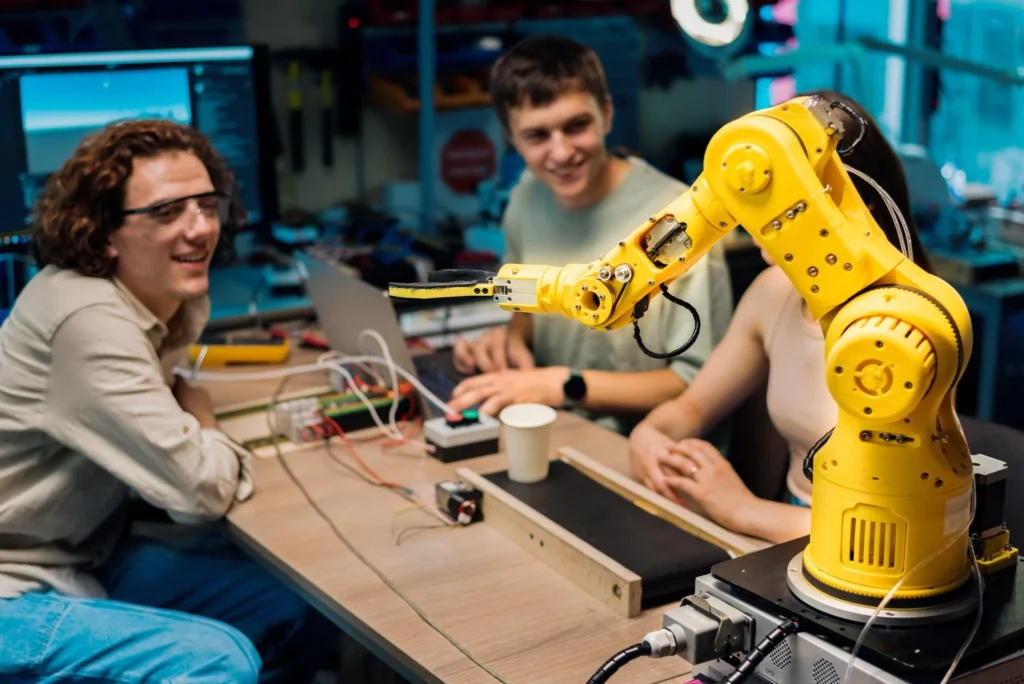

Autonomous Robotics & Cobots

AI-enabled collaborative robots are transforming factory floors by 25–30% throughput improvement.

It increases safety for workers in repetitive or dangerous tasks, and payback periods are around 18 months. Cobots assist humans in concentrating on higher‑value activities, increasing overall productivity.

Read our case study, “A Case Study on Teams Integrated AI Chatbot,”.In this study, our implements solutions that automate communications and knowledge access in manufacturing environments.

Factory-in-a-Rack & Edge AI

If the factory area is large, up to 30 square meters (less than 100 feet of square footage), pre-built AI models and edge AI platforms make it fast to test environments. This model reduces risk and initial cost. It requires weeks, not quarters, to deploy proofs-of-concept. Finally, its scale-out infrastructure allows for incremental roll‑out.

Process Optimization and Automation

Another major area for AI implementation is intelligent process automation. Manufacturers are applying AI services to streamline the production process, prevent waste, and optimize overall equipment effectiveness (OEE). Such solutions use classical automation and AI to produce adaptive, self-improving systems.

Why Xorbix is Your Ideal AI Partner

Xorbix Technology is ideal for several reasons. Some of them are given below:

End-to-End AI Services

We take you from AI strategy workshops to production MLOps deployments. Our AI services seamlessly slot into your existing ERP, MES, and SCADA platforms, no factory reboot needed. Strategy Workshops to MLOps-in-production, Xorbix Tech team provides end-to-end AI solutions that easily plug into current MES/ERP stacks.

Custom AI Development Crafted for You

Looking for a custom computer-vision model or generative design that is unique to your parts or process? Our A.I. and custom ML models are based on your data, so your model will continue to provide trends and results that can be easily customized over time. Our AI development teams build models that are customized for your specific data.

Scalable AI Solutions for Manufacturing

Our AI product offerings are built for scale, edge to cloud. We support everything from micro-PoCs to site-wide rollouts with GPU pods, Kubernetes, and production-level monitoring. Our scalable, cloud-native, edge-ready solutions are built for high-availability manufacturing operations. They demonstrate that Xorbix is not just solving but actually building solutions, and here is your measurable ROI to go along with it.

Conclusion

US industry leaders are implementing AI and machine learning with ‘smart’ upgrades in predictive maintenance, computer-vision quality inspection, supply chain forecasting, and robotic automation. Manufacturers realize that maintenance can be transformed from a reactive process to a predictive one by using AI-based development services. It saves a substantial amount of costs, improving efficiency and productivity.

Visit our guides about how AI is adopted in the manufacturing sector:

- The Manufacturing Efficiency Revolution: Custom AI and the Future of Productivity

- Custom AI in Manufacturing: 7 Ways to Boost Workforce Productivity

- Workplace Safety in Manufacturing: How Custom AI Helps Prevent Accidents

FAQs

How is AI impacting the US manufacturing sector?

AI services and AI development solutions enable companies minimize keep downtime to minimize downtime, increase throughput, and shorten the product cycle. It results in greater operational efficiency and profitability.

What are the applications of AI and machine learning in manufacturing?

Predictive maintenance, quality control with AI, supply chain optimization, generative design, and robotic automation solutions bring rapid ROI by limiting waste, lowering defect rates, and speeding up production.

How can AI be deployed by smaller manufacturers?

Small manufacturers can start with low-risk pilot projects, like rolling out predictive analytics on a single production line, before they make the technology enterprise-wide.

What ROI can manufacturers expect from AI implementation?

For most manufacturers, AI solutions start to generate ROI within 6-18 months. That could mean dropping equipment downtime by 30% using predictive maintenance, or cutting defect rates in half through AI-driven quality inspection systems.

What should manufacturing executives keep in mind when evaluating an AI services provider?

Find a partner with end-to-end AI capabilities that knows how manufacturing works and can demonstrate success through case studies. Xorbix Technologies will take you through strategy workshops, develop and maintain custom models.