Workplace Safety in Manufacturing: How Custom AI Helps Prevent Accidents

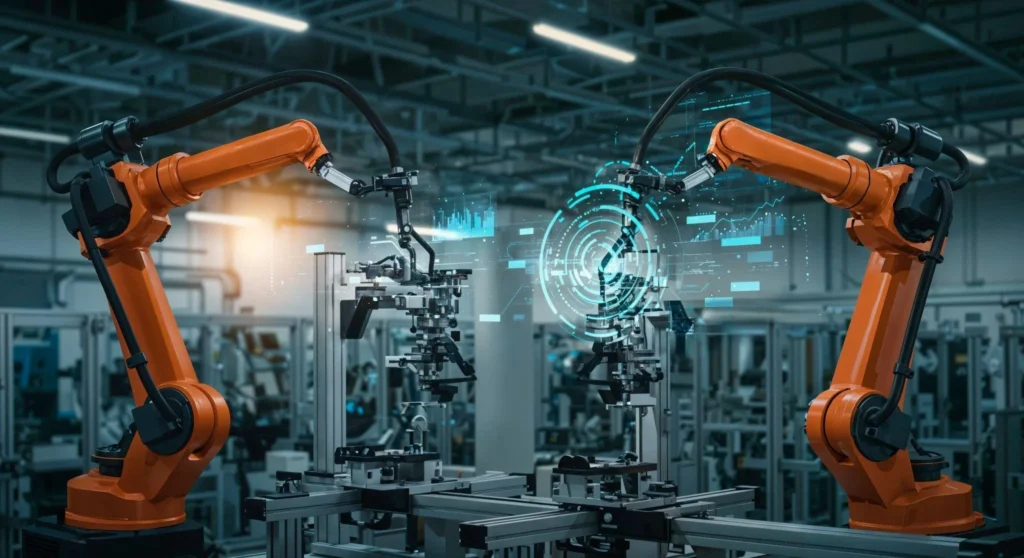

Custom AI revolutionizes manufacturing by making plants safer places to work and cutting down on accidents.

Custom AI in Manufacturing: 7 Ways to Boost Workforce Productivity

Pressure on manufacturing leaders is at an all-time high to streamline operations by maintaining quality and safety protocols.

The Manufacturing Efficiency Revolution: Custom AI and the Future of Productivity

In today’s fast-paced business world, companies need to innovate to stay ahead.

Top Strategies for Keeping Manufacturing Data Secure with IT Security Services in 2025

Today’s manufacturing companies are under constant cyber threat, which can disrupt production, steal valuable data, and cause losses of millions of dollars.

Why Businesses Are Moving to Databricks for Scalable Cloud Analytics

As cloud adoption accelerates, businesses are increasingly turning to Databricks, a unified analytics platform built on Apache Spark, to address these challenges and unlock the full potential of their data.

Can Databricks Enhance Operational Efficiency for Modern Businesses?

In today’s fast-paced digital world, businesses are constantly seeking ways to optimize their operations and stay ahead of the competition.

Driving Financial Wellness Through Custom Digital Solutions

A socially conscious fintech innovator approached Xorbix with an ambitious goal: empower consumers to easily access trusted local nonprofit and government financial assistance resources.

How Chicago’s Manufacturing Sector is Using AI to Stay Competitive?

Chicago, long known as a hub for manufacturing and industrial innovation, is now embracing artificial intelligence (AI) to maintain its competitive edge in a rapidly evolving global market.

Why Do Businesses Need Personalized AI Solutions for Competitive Advantage?

In today’s fast-paced digital world, businesses that fail to adapt quickly risk falling behind.

Optimizing Production with AI-Powered Automation in New York’s Factories

What if your factory could predict equipment failures before they happen, adjust production lines in real-time, and slash waste without human intervention?